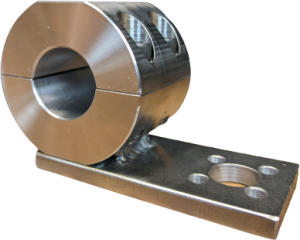

Choose a clamp collar

These machined steel collars provide a convenient and robust method for joining tube and bar stock with English O.D.’s 3/4, 1, 1 1/4, 1 1/2, 1 3/4. Any combination of sizes is permitted at any angle. Tubing may be of any suitable material with a size compliant O.D.

The construction roll pins may be used to secure the collars to each other or to custom plates and components for consistent and accurate welding.

Roll pin locating provides instant precision setups set ∥ , ⊥ , or at any angle, clamp to clamp.

Pre-machining roll pin holes in plates provides an instant true position for welding on plates.

- 1018 steel no finish provides consistent welds

- Flats provide 2x stronger welds

- Flats provide easy welding of handles and extensions to top of collars

- No black oxide or plating to remove before welding

- 6061 Aluminum versions available in select sizes

- Heavier wall section = Higher strength & more thread engagement

- All M-6 x 1 fasteners / No mixed sizes or fine threads

For custom coatings or component assemblies please upload and send prints below.

These Mighty shaft collars are all exactly the same with no effort. Weld penetration is excellent and rapid. I am in Love with the Mighty shaft collar.

Using the roll pin assembly method saved me 2.5 Hours of fixturing time making these assemblies!

The Black oxide option was excellent for a finished version with no scratches